1. Double sided aluminum substrate

Introduction to double-sided aluminum substrate products:

The double-sided aluminum substrate inherits the metallicity and safety of a single-sided aluminum substrate, and can also achieve complex and precise wiring for ordinary circuit boards (FR4 PCBs). The double-sided aluminum substrate perfectly applies the characteristics of heat dissipation aluminum, conductive copper, insulation resin, and thermal conductive film to electronic circuit boards. The double-sided aluminum substrate can be independently wired on both sides of the product, and can also form a larger network by communicating the lines on both sides through electroplating through holes. Make the wiring design of double-sided aluminum substrate more flexible, which can meet more complex work fields. Capable of filling both sides of the product with "SMT", wiring, and binding. The double-sided aluminum substrate integrates efficient thermal conductivity, heat dissipation, safe insulation, and long service life.

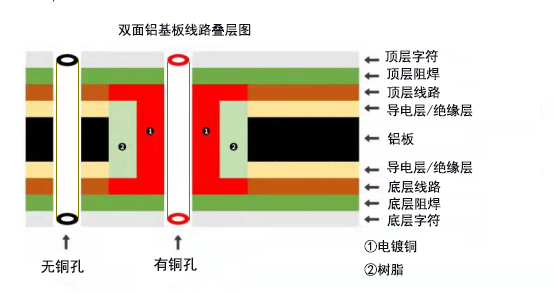

2. Structural diagram of double-sided aluminum substrate products

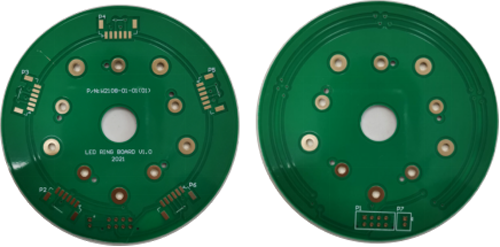

3. Schematic diagram of the front and back of the double-sided aluminum substrate product

4. Manufacturing instructions for double-sided aluminum substrate product production and production process:

Substrate: Aluminum (5052)

Thickness: 0.8/1.0/1.2/1.5/1.6/2.0/2.5/3.0MM

Thermal conductivity (dielectric layer) 1/1.5/2.0/3.0 W/m.K

Copper foil thickness: 0.5/1/2/3/4 OZ

Solder resistance color: white/black/matte black/red/green/blue/matte green

Character color: white/black/orange/red/blue

Forming method: CNC gongs, CNC V-cutting, mold forming, laser cutting and milling

Surface treatment process: Lead sprayed tin, lead-free sprayed tin, chemical gold precipitation (gold thickness 0.5U "~3.0U"), chemical nickel palladium gold OSP

Delivery time: 6-8 days.

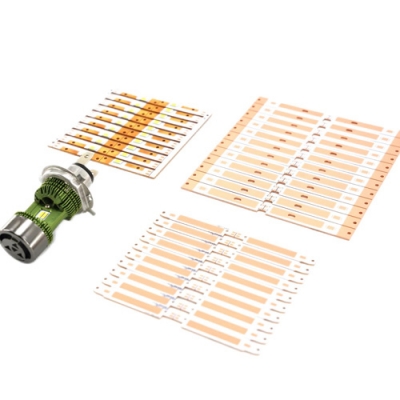

5. Application occasions of double-sided aluminum substrate products:

Flashlights, industrial mining lights, automotive LED lights, stage projection lights, projection equipment, wall washing lights, LED street lights, and various precision and high demand heat dissipation lighting instruments

6. Advantages of double-sided aluminum substrate products:

Long service life, efficient heat dissipation, stable performance, and wide application range