1、 Introduction to Single sided Insulated Hole Aluminum Substrate:

Due to the fact that metal core aluminum is a conductor and cannot fix DIP components, insulation hole technology is the solution to this problem.

The insulation hole aluminum substrate material is composed of aluminum plate (5052), dielectric layer, and copper layer. The difference between insulated hole aluminum substrate and single-sided aluminum substrate PCB is that the aluminum is pre drilled, filled with epoxy resin adhesive, and the dielectric layer and copper layer are pressed onto it. The main convenience for DIP components is to pass through the gaps in the aluminum through the wire through holes to maintain electrical insulation. The aluminum core can allow for electrical connection and insulation through holes, which is called the insulation hole aluminum substrate.

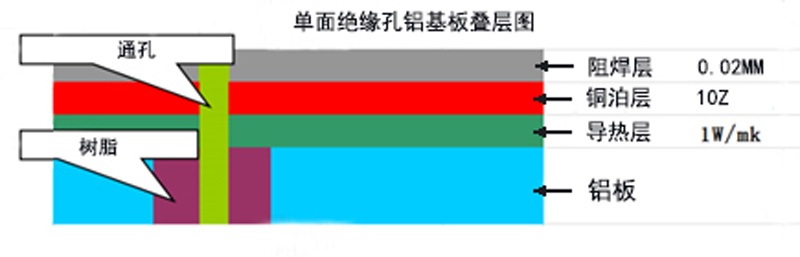

2、 Schematic diagram of insulation holes on single sided aluminum substrate:

3、 The structure of single-sided insulated hole aluminum substrate is shown in the following figure:

4、 Special process for single-sided thermoelectric separation insulation hole aluminum substrate

1. Countersunk hole

2. Depth control hole/groove

5、 Parameters of Single sided Insulated Hole Aluminum Substrate

1. Plate thickness: 0.8MM~3.0MM (plate thickness tolerance ± 10%)

2. Copper foil thickness: 35um~105um (copper foil tolerance ± 10%)

3. Resistance welding color: white/black/red/blue/green oil

4. Character color: black/white

5. Surface treatment: sinking gold, lead-free tin spraying, lead-based tin spraying, OSP

6. Shape forming method: V-CUT, CNC, die punching

7. Delivery time: 4-5 days

8. Application areas: Automotive LED lights, medical equipment, mechanical equipment, DIP packaging

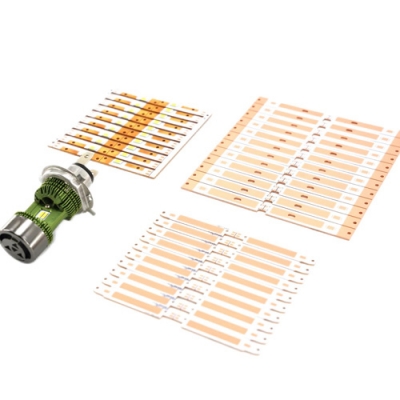

6、 Single sided insulated hole aluminum substrate product application scenarios:

Flashlights, industrial mining lights, automotive LED lights, stage projection lights, projection equipment, wall washing lights, LED street lights, and various precision and high demand heat dissipation lighting instruments

7. Advantages of Single sided Insulated Hole Aluminum Substrate Products:

Metal components have a long service life, efficient heat dissipation performance, stability, and a wide range of applications.